Returnable Soft Drink Tray

Effortless handling saving time, cost and resources

Client

Albert Heijn + Coca-Cola

Services

Context

Labour-intensive bottle handling

When FLEX/design got involved in this project, the main cause was an internal calculation made by Albert Heijn. It showed that the labour costs for distributing fast-moving products like Coca-Cola were estimated at EUR 18 million annually (adjusted for 1995 values). The goal was to significantly reduce these costs across the distribution chain.

From linear systems to circular systems

Retail supply chains have used circular solutions like pool systems and plastic crates for years, including for Coca-Cola bottles. To stay competitive with cheaper, linear options, these systems needed a redesign to remain cost-efficient.

Concept

Inspired by egg packaging

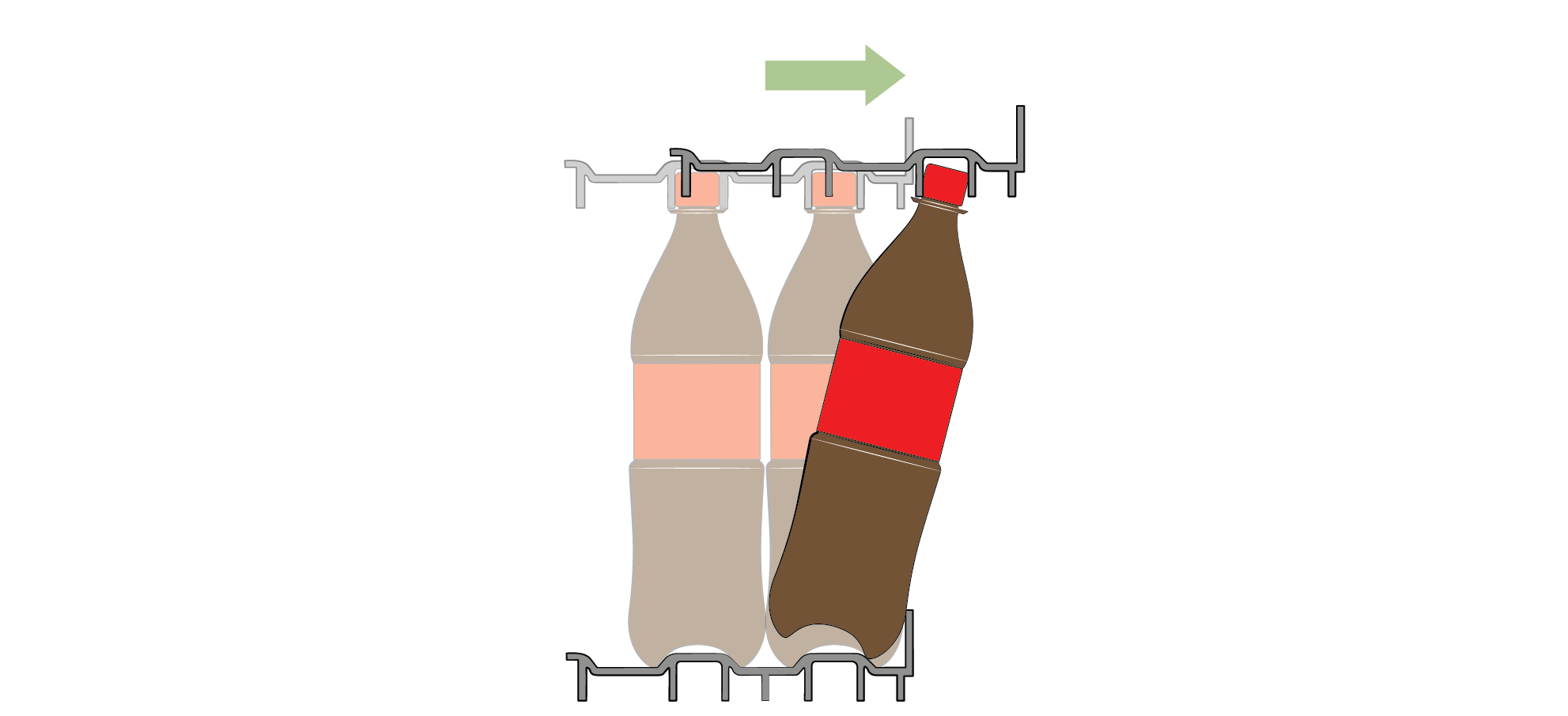

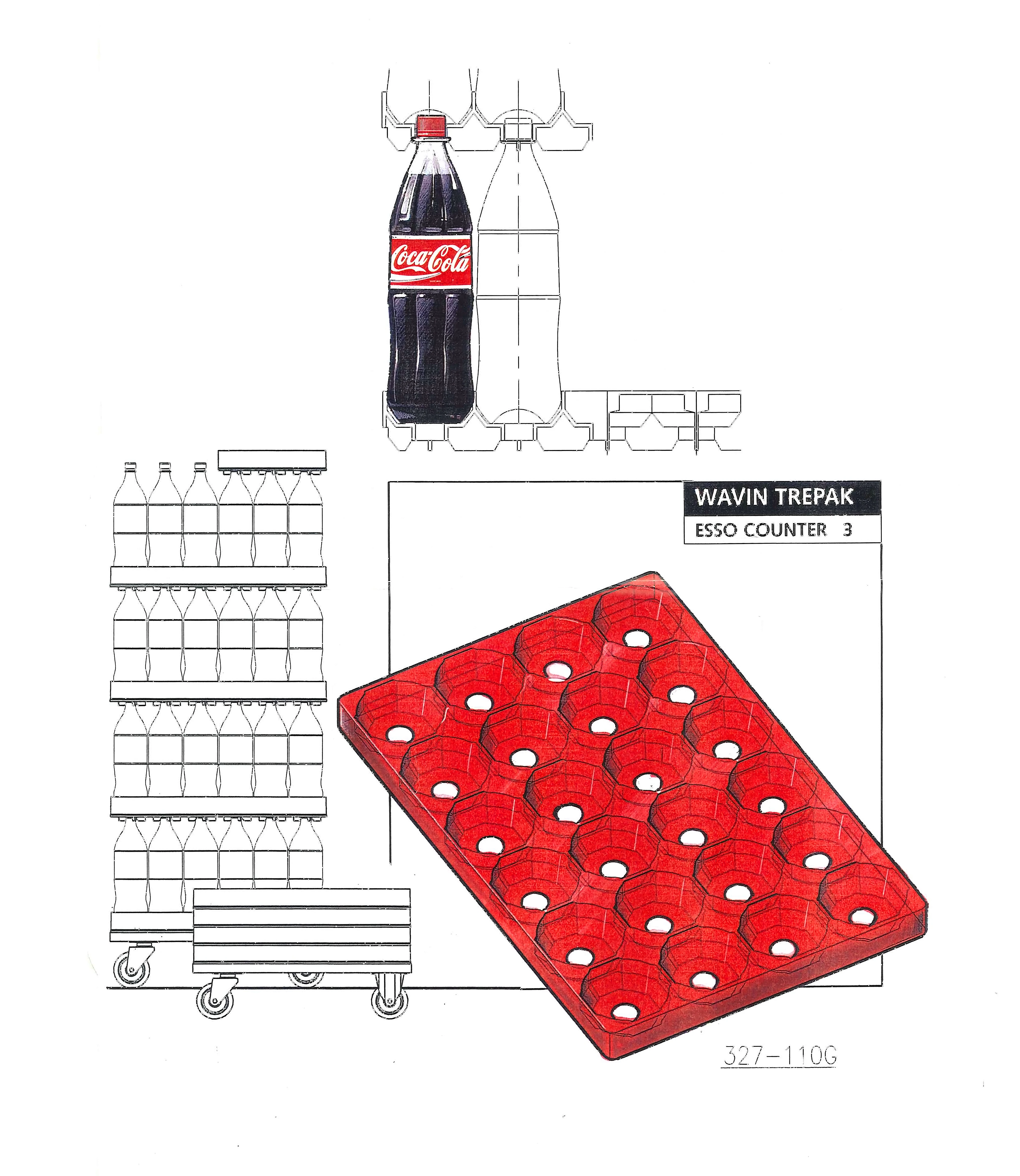

Various concepts were explored, including a steel-plastic dolly and a stackable display crate. Coca-Cola initially requested a solution that fully supported the bottles like existing crates, but this approach was re-framed. The team got inspired by industrial egg-trays, where the eggs carry each other.

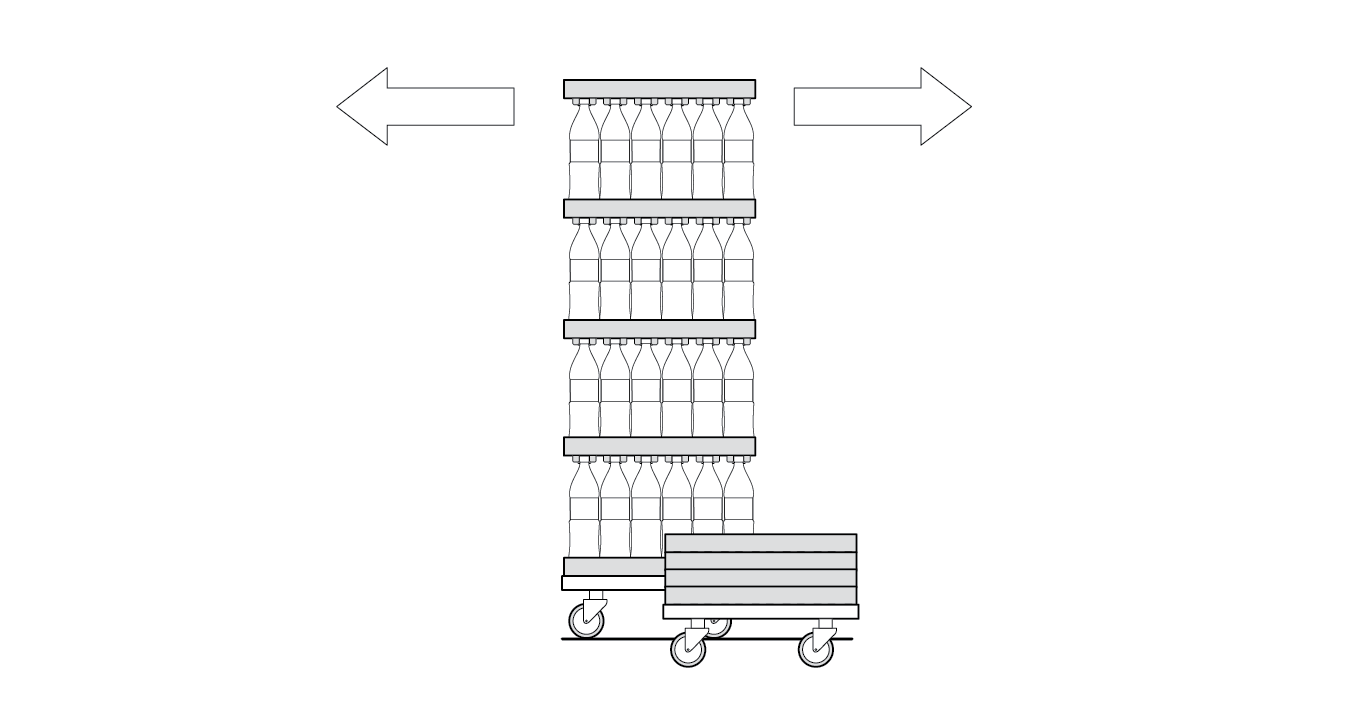

Stability with minimal geometry

Accelerate

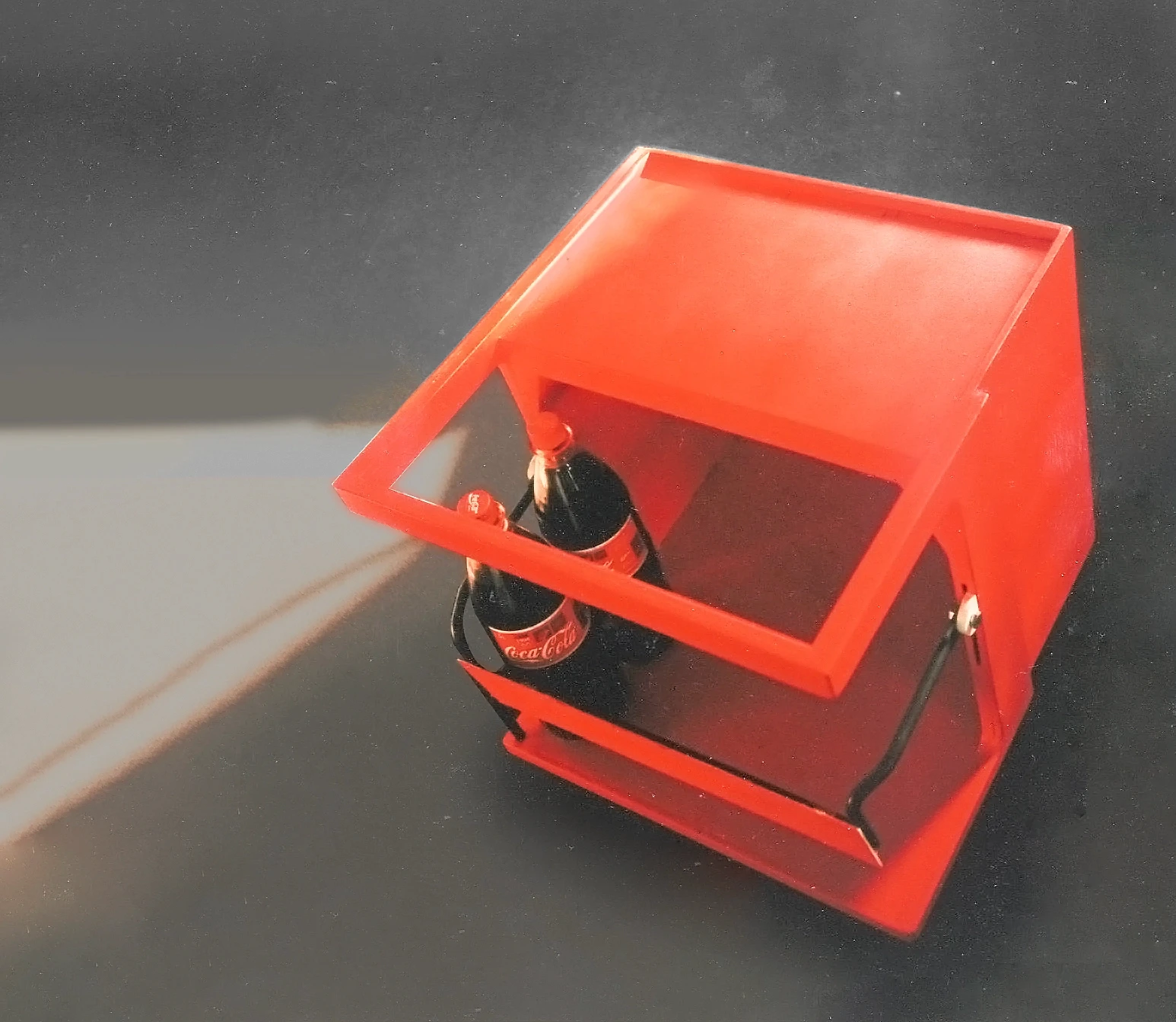

Solutions to align all stakeholders

By bringing stakeholders together early and creating prototypes, we foster powerful alignment and clarity in the project. This collaborative approach enabled quick reflection, creating the right conditions to re-frame the project and effectively solve the problem.

Other work

towards local production